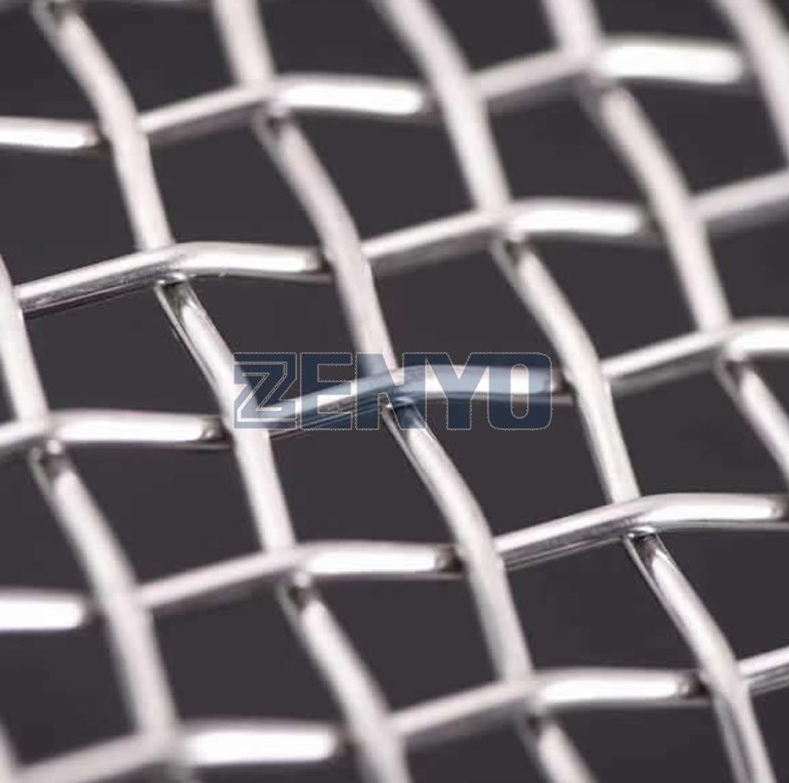

# The best steel for cold forming.

Cold forming refers to the process of shaping metal at room temperature, giving the metal enhanced hardness and strength. When it comes to selecting the best steel for cold forming, there are a few key factors to consider. In this guide, we'll outline the steps to help you choose the right steel for your cold forming needs.

## Step 1: Understand the requirements.

Before selecting a steel for cold forming, it's important to understand the specific requirements of your project. Consider factors such as the desired final shape, the complexity of the part, and the level of precision required. Different steels have different properties, so knowing your project requirements will help you narrow down your options.

## Step 2: Select a steel grade.

Once you have a clear understanding of your project requirements, it's time to choose a steel grade. Some common grades of steel used for cold forming include low carbon steels, medium carbon steels, and high-strength low alloy (HSLA) steels. Each grade has its own unique properties that make it suitable for specific applications.

## Step 3: Consider the formability.

Additional resources:Top Tips for Choosing 304 Stainless Steel BarIs Cold Heading Quality the Secret to Success?Why Premium Steel Wire Rods are Essential?How Does Silicon Rubber Washers Work?5 Tips for Choosing the Best Ceramsite Sand?Carbon Steel Rod: The Ultimate Guide for Crafting?The Benefits of Annealed Stainless Steel TubingFormability is a key factor to consider when choosing a steel for cold forming. High formability steels are easier to shape and bend, making them ideal for complex parts with tight tolerances. Low formability steels, on the other hand, are more difficult to shape but offer higher strength and hardness. Consider the formability of the steel grade based on your project requirements.

## Step 4: Evaluate the mechanical properties.

In addition to formability, it's crucial to evaluate the mechanical properties of the steel grade. This includes factors such as tensile strength, yield strength, and elongation. Choose a steel grade with mechanical properties that are suited to your project requirements, ensuring the final part meets the desired performance standards.

## Step 5: Consult with a metallurgist.

If you're unsure about which steel grade is best for your cold forming project, consider consulting with a metallurgist. A metallurgist can provide expert advice on selecting the right steel grade based on your specific requirements. They can also offer guidance on heat treatment processes and other factors that may affect the cold forming process.

By following these steps and carefully considering your project requirements, you can choose the best steel for cold forming. Whether you need a high formability steel for complex shapes or a high-strength steel for demanding applications, selecting the right steel grade is essential for achieving successful cold forming results.

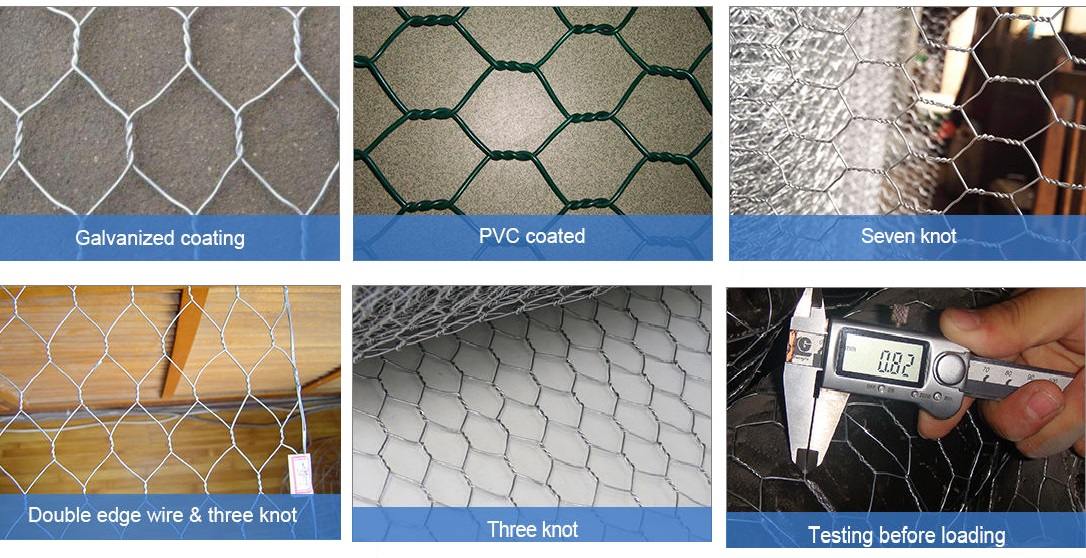

Are you interested in learning more about Wire Fittings Wholesale, Cold Heading Quality Wire Supplier, Wire Fittings? Contact us today to secure an expert consultation!

Additional resources:How is Medium-Carbon Steel Produced?Blog Sand Casting Process: Advantages and LimitationsBarbed Wire: Securing Boundaries with Uncompromising ProtectionMagnesia Carbon Brick: A High-Performance Refractory SolutionHow Does a 358 Security Fence Differ from Other Types of Fences?Prestressing Strand: Revolutionizing Structural EngineeringHow to Prevent 3 Common Metal Filter Problems

Comments

All Comments ( 0 )