For more information, please visit CHIDA.

Ferroalloys play a crucial role in the world of metallurgy, providing essential properties to steel and other metal alloys. From enhancing strength and durability to improving corrosion resistance and electrical conductivity, ferroalloys are indispensable in various industries.

In this ultimate guide, we will delve deep into the intricate process of ferroalloy production, shedding light on the key steps involved, the types of ferroalloys produced, and the significance of quality control measures.

Ferroalloy Production Process Overview.

The production of ferroalloys is a complex and highly specialized process that requires expertise and precision. The process typically begins with the selection of raw materials, which are carefully chosen based on the desired properties of the final ferroalloy product.

The raw materials used in ferroalloy production are primarily metal oxides, such as iron ore and manganese ore, along with carbonaceous materials like coke or coal. These raw materials are blended in precise proportions to achieve the desired chemical composition of the ferroalloy.

The next step in the production process involves smelting the raw materials in a high-temperature furnace. The furnace is typically a submerged arc furnace or an electric arc furnace, depending on the type of ferroalloy being produced. The temperature inside the furnace can reach up to 2000 degrees Celsius, causing the raw materials to melt and react with each other to form the desired ferroalloy.

During the smelting process, various reactions take place, leading to the reduction of metal oxides and the formation of molten ferroalloy. Fluxes are often added to the furnace to facilitate the separation of impurities and improve the quality of the final product.

Once the smelting process is complete, the molten ferroalloy is tapped from the furnace and poured into molds to solidify. The solidified ferroalloy is then crushed and screened to the desired size before being packaged and shipped to customers for further processing.

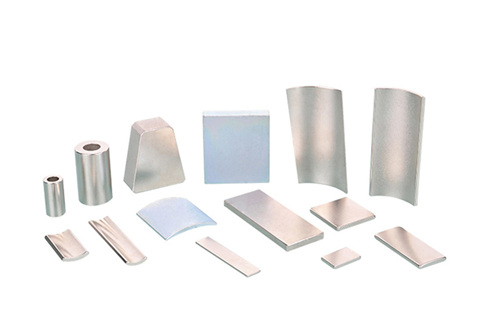

Types of Ferroalloys.

There are a wide variety of ferroalloys produced around the world, each with unique properties and applications. Some of the most commonly produced ferroalloys include:

- Ferrochrome: Used in stainless steel production to improve corrosion resistance and high-temperature strength.

Additional resources:Top Tips for Choosing 304 Stainless Steel BarIs Cold Heading Quality the Secret to Success?Why Premium Steel Wire Rods are Essential?How Does Silicon Rubber Washers Work?The Benefits of Cast Aluminium Garden FurnitureWhich industries commonly use color-coated steel coils?Know about Titanium Dioxide- Ferromanganese: Enhances the strength and toughness of steel, particularly in high-carbon applications.

- Ferrosilicon: Increases the hardness and wear resistance of steel, as well as improving its magnetic properties.

- Ferrovanadium: Imparts strength and heat resistance to steel, making it ideal for high-stress applications.

Quality Control in Ferroalloy Production.

Quality control is of utmost importance in ferroalloy production to ensure the consistency and reliability of the final product. Various measures are taken throughout the production process to monitor and maintain quality standards.

One critical aspect of quality control in ferroalloy production is the analysis of raw materials before they are used in the furnace. By testing the chemical composition and physical properties of the raw materials, manufacturers can ensure that the final ferroalloy meets the required specifications.

In addition, the temperature and atmosphere inside the furnace are carefully monitored and controlled to optimize the smelting process and prevent the formation of impurities. Regular sampling and analysis of the molten ferroalloy are also conducted to check for any deviations from the desired composition.

Furthermore, the crushing and screening of the solidified ferroalloy are conducted with precision to ensure that the final product meets the customer's size requirements. Any oversize or undersize particles are separated and recycled to maintain the quality of the product.

In conclusion, ferroalloy production is a complex and highly specialized process that requires expertise, precision, and attention to detail. By understanding the key steps involved in the production process, the types of ferroalloys produced, and the importance of quality control measures, manufacturers can ensure the consistent quality of their products and meet the increasing demand for ferroalloys in various industries.

You can find more information on our web, so please take a look.

For more information, please visit Silica Quartz Powder.

Additional resources:A Comprehensive Guide to Plate Disposable FilterWhat is hinge joint fence?High Bulk Density Graphite Block: The Ultimate GuideAdvantages and Applications of Grey Iron CastingDifferent Types of Aluminum CastingChoosing the Right Mesh Filters: Factors to ConsiderBenefits of Sintered Porous Metal Filter Element

Comments

All Comments ( 0 )