One of the most commonly used hardware accessories in material handling, eye bolts are simple in design and consist of a threaded shank with a ring/eye at one end. Eyebolts are connected to structures such as wooden or steel posts and are often supported by a nut. They are designed to have a rope or cable passing through the ring in order to lift objects.

This ring can be drop forged (one single piece, with eyes completely closed) or bent to form a loop. Bent eye bolts can only be used for light applications and must not be used for corner lifting.

Eyebolt installation and maintenance

Just as it is important to choose the correct eye bolt, correct installation and maintenance are the keys to ensuring the safety of the workplace.

Installation guide and tips:

• The receiving hole should be a counterbore without any debris to ensure proper sealing.

• Be sure to check and clean the threads and holes of the eye bolts before use.

• The load should always be aligned with the plane of the eye, not at an angle to the plane. A steel washer or a spacer can be used with shoulder eye bolts to achieve proper load alignment. The thickness of the steel washer or spacer must not exceed one pitch.

• Check the valve seat after applying an angular lift, as the initial lift may cause the bolt to deviate from the load. If this happens, the eye bolts should be removed and reinstalled correctly.

• For applications with untapped through holes, it is recommended to use longer-length shoulder eye bolts, and steel washers and nuts according to the required thread length.

• Shoulder eye bolt tapping holes have a threaded length, allowing full-length engagement of the shank and clearance of the unthreaded part of the shank.

Shoulder eye bolts must be firmly fixed on the mating surface; otherwise, the rated capacity will be significantly reduced. The use of steel washers or spacers is permitted and may be necessary; however, the thickness cannot exceed one thread pitch.

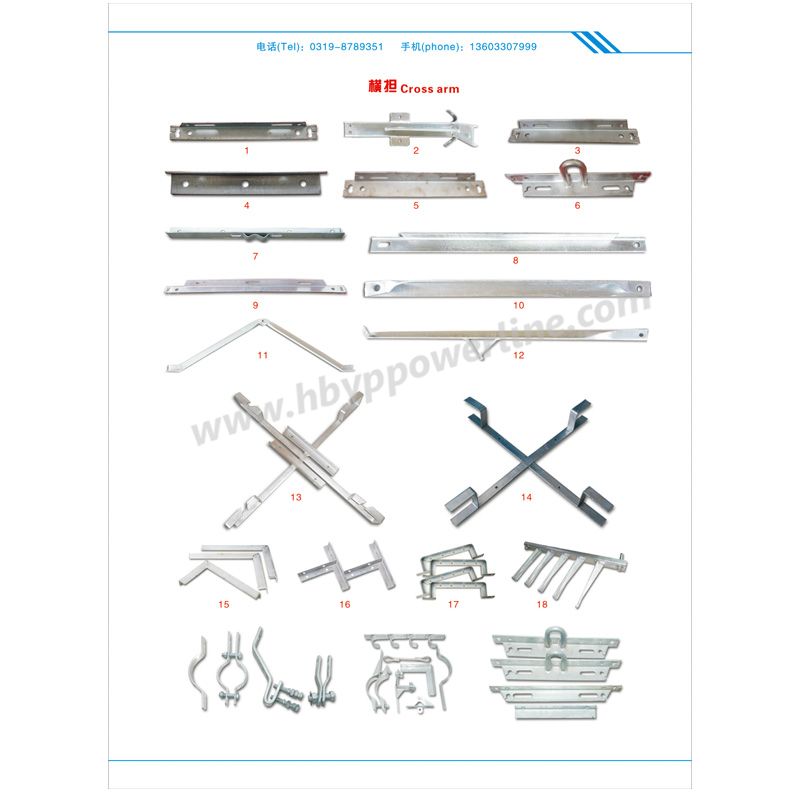

Additional resources:What is the cross arm of the transmission line?Parallel Groove Clamps PGParallel Groove (PG) Clamps for overhead linesTypes of Utility Poles- The Ultimate GuideStrain Clamp - Handan Dapeng Power Equipment ...The Benefits of Using OPGW in Transmission LineUnlocking the Mystery: Arcing Horns in TransmissionEyebolts

• The tap holes of plain eye bolts should be threaded for full-length engagement of the eye bolts.

• Plain eye bolts must have full threaded shank engagement, allowing for a one-half turn, and obtain rated capacity with proper eye alignment.

• Align the eye bolts with the sling. If the load is applied sideways, the eye bolt may bend.

• Pack the washer between the shoulder and the load surface to ensure that the eyebolt firmly touches the surface. Make sure that the torque of the nut is appropriate.

• When using shims or washers, engage at least 90% of the threads in the hole.

• Do not install more than one lifting leg on the eye bolt.

• Always pass the eyebolt through and ensure the correct seating

• Make sure that the depth of the tapped hole of the screw eye bolt (body bolt) is not less than 1.5 times the bolt diameter.

• The mounting shoulder is at right angles to the axis of the hole. The shoulders should be in full contact with the surface of the object being lifted.

We are Eye bolt suppliers. Please feel free to contact us if you need or want to know about eye bolts.

Additional resources:Revolutionary Uses of Bent Eye Bolts: Ideas?Choosing the Right Bolt: Lag vs CarriageHammer Buying Guide4 Advice to Choose Diamond Tools for Ohio GravureExploring the Benefits of Using Gravure Diamond ToolsUnlocking the Benefits of Using Sharp Point Diamond Turning ToolsAnode Answers for Hard Chrome Plating

Comments

All Comments ( 0 )