Introduction

In the world of electricity, various components play vital roles in ensuring the safe and efficient distribution of power. One such component is the cross arm. But what exactly is a cross arm in electricity? In this article, we will explore the definition, purpose, installation, and importance of cross arms in electrical systems. We will delve into its various types, materials used, and common FAQs surrounding this crucial element of the power grid.

What is a Cross Arm in Electricity?

A cross arm, also known as a crossarm or a cross brace, is a horizontal beam-like structure that provides support and stability to overhead power lines. It is typically made of wood or metal and is mounted on utility poles. The primary function of a cross arm is to bear the weight of power conductors and insulators while maintaining the required clearance between electrical components.

The cross arm acts as a crucial intermediary between the pole and the conductors, facilitating the safe and efficient distribution of electricity. It provides a secure platform for attaching various hardware, such as insulators, brackets, lightning arrestors, and other accessories required for the reliable operation of power lines.

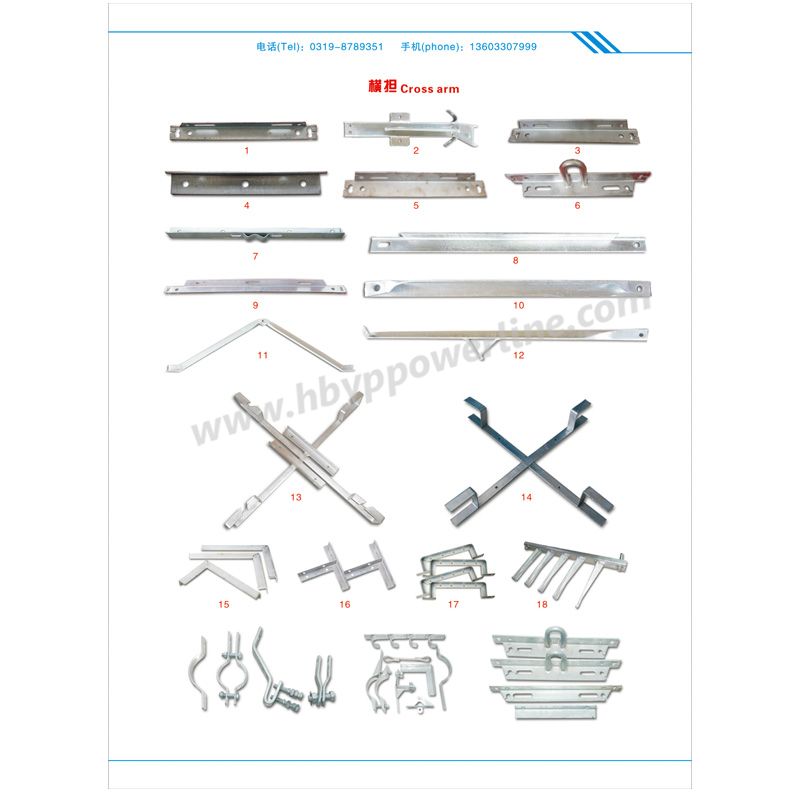

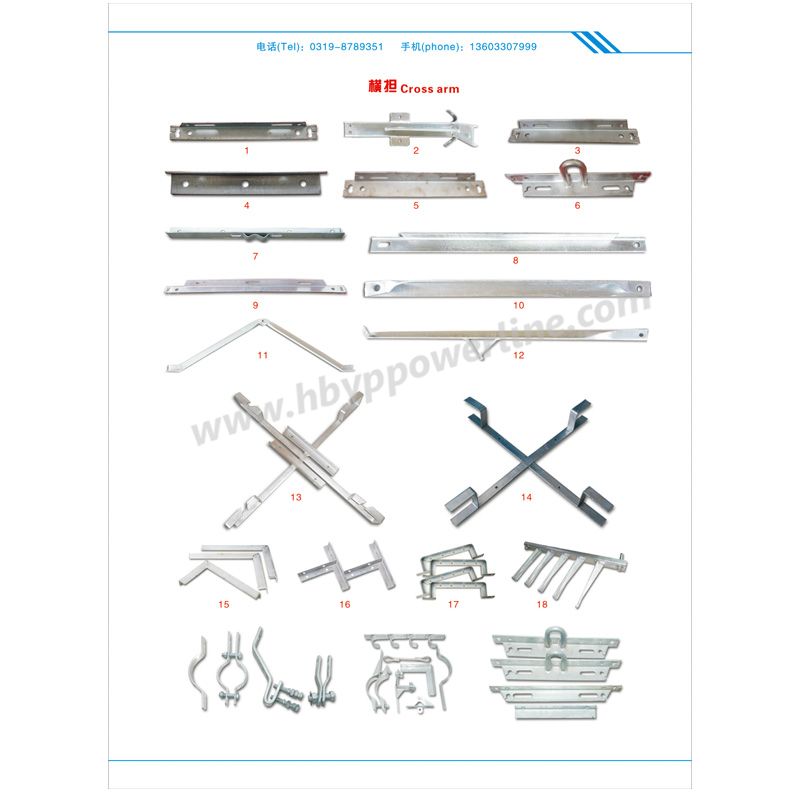

Types of Cross Arms

There are different types of cross arms used in electricity distribution systems, each catering to specific requirements and load capacities. Let's explore some common types:

1. Straight Cross Arm

The straight cross arm is the most basic and widely used type. It is a horizontal beam that runs perpendicular to the utility pole, providing support to the electrical conductors. Straight cross arms are often made of durable materials such as hardwood or treated softwood to withstand the harsh outdoor conditions.

2. V-Type Cross Arm

The V-type cross arm derives its name from its distinctive shape, resembling the letter "V." This type of cross arm provides extra strength and stability, making it suitable for areas with high wind or heavy ice loads. The V shape helps in reducing stress on the cross arm and the pole, minimizing the risk of structural failures.

3. Alley Arm

An alley arm, also known as a corner arm, is a specialized type of cross arm designed for power line intersections or corners. It allows power lines to change direction while maintaining the necessary clearance and stability. Alley arms are typically longer than regular cross arms to accommodate the angle changes.

Materials Used in Cross Arms

Cross arms are manufactured using various materials, each offering distinct advantages in terms of strength, durability, and cost-effectiveness. The choice of material depends on factors such as environmental conditions, load requirements, and budget considerations. The most common materials used in cross arms are:

1. Wood

Wooden cross arms have been widely used in the power industry for many years. They are typically made from treated hardwood or softwood, such as Douglas fir, cedar, or pine. Wood offers excellent electrical insulation properties and is relatively affordable compared to other materials. However, wooden cross arms require regular maintenance to prevent rot, insect infestation, and weathering.

2. Fiberglass

Fiberglass cross arms have gained popularity in recent years due to their exceptional strength, light weight, and resistance to environmental factors. Fiberglass offers excellent electrical insulation properties and is immune to rot, rust, and corrosion. Additionally, it requires minimal maintenance, making it a cost-effective long-term solution for power distribution systems.

3. Steel

Steel cross arms are known for their superior strength and durability. They are commonly used in high-voltage transmission lines and areas prone to extreme weather conditions. Steel offers excellent load-bearing capacity and can withstand heavy ice, wind, and other environmental stresses. However, steel cross arms are susceptible to corrosion and require protective coatings or galvanization to enhance their lifespan.

Installation of Cross Arms

Proper installation of cross arms is crucial to ensure the structural integrity and safe operation of power lines. Here are the general steps involved in installing a cross arm:

Preparation: Before installation, ensure all necessary tools, equipment, and materials are available. Conduct a thorough inspection of the utility pole and ensure it is in good condition.

Positioning: Determine the appropriate height and position for the cross arm on the pole. Take into account factors such as clearance requirements, load capacity, and nearby obstacles.

Attachment: Securely fasten the cross arm to the pole using appropriate hardware, such as bolts, brackets, or straps. Ensure the attachment is tight and stable to withstand the weight of the conductors.

Conductor Placement: Install the power conductors onto the cross arm, ensuring proper spacing and tension. Attach insulators and other necessary hardware to maintain the required clearance and prevent electrical faults.

Safety Measures: Throughout the installation process, adhere to all safety guidelines and protocols. Use personal protective equipment (PPE) and take precautions to avoid electrical hazards.

Inspection: After installation, conduct a thorough inspection to ensure the cross arm, hardware, and conductors are properly installed and secured. Address any issues or discrepancies promptly.

FAQs about Cross Arms in Electricity

Q: How long does a cross arm last? A: The lifespan of a cross arm depends on various factors, including the material used, environmental conditions, and maintenance practices. Generally, wooden cross arms last around 15 to 25 years, while fiberglass and steel cross arms have longer lifespans of 30 to 50 years or more.

Q: Can cross arms be replaced without interrupting power supply? A: Yes, it is possible to replace cross arms without interrupting the power supply. However, careful planning and coordination with the utility company are required to ensure a smooth transition. Temporary supports or alternative power routes may be employed during the replacement process.

Q: How are cross arms inspected for damage? A: Cross arms are visually inspected for signs of damage, such as cracks, rot, or insect infestation. Inspectors may also use specialized tools, such as borescopes or ultrasonic devices, to assess the internal condition of the cross arm. Regular maintenance and inspection schedules are essential to identify and address potential issues promptly.

Q: What are the consequences of a failed cross arm? A: A failed cross arm can lead to various issues, including sagging or falling power lines, electrical faults, interruptions in power supply, and safety hazards. It can also cause damage to surrounding structures and pose risks to personnel working in the vicinity.

Q: Can cross arms be repaired, or do they need to be replaced entirely? A: In some cases, minor damage to a cross arm can be repaired by reinforcing or replacing specific sections. However, extensive damage or signs of structural compromise often require the complete replacement of the cross arm to ensure the safety and reliability of the electrical system.

Q: What are the safety precautions while working with cross arms? A: When working with cross arms, it is crucial to follow safety protocols, including wearing appropriate PPE, using insulated tools, and maintaining a safe distance from energized components. Proper training, awareness of electrical hazards, and adherence to safety guidelines are essential to prevent accidents and injuries.

Conclusion

In the realm of electricity distribution, cross arms play a vital role in supporting power lines, ensuring their stability, and maintaining the required clearance. They serve as critical components in the safe and efficient delivery of electrical energy. Whether made of wood, fiberglass, or steel, cross arms provide the necessary strength and durability to withstand various environmental conditions and load requirements.

Understanding the purpose, types, materials, and installation process of cross arms is crucial for professionals in the electrical industry and anyone seeking knowledge about power distribution systems. By ensuring proper maintenance, periodic inspections, and timely replacements, we can enhance the reliability and longevity of cross arms, contributing to a robust and resilient electrical infrastructure.

Comments

All Comments ( 0 )