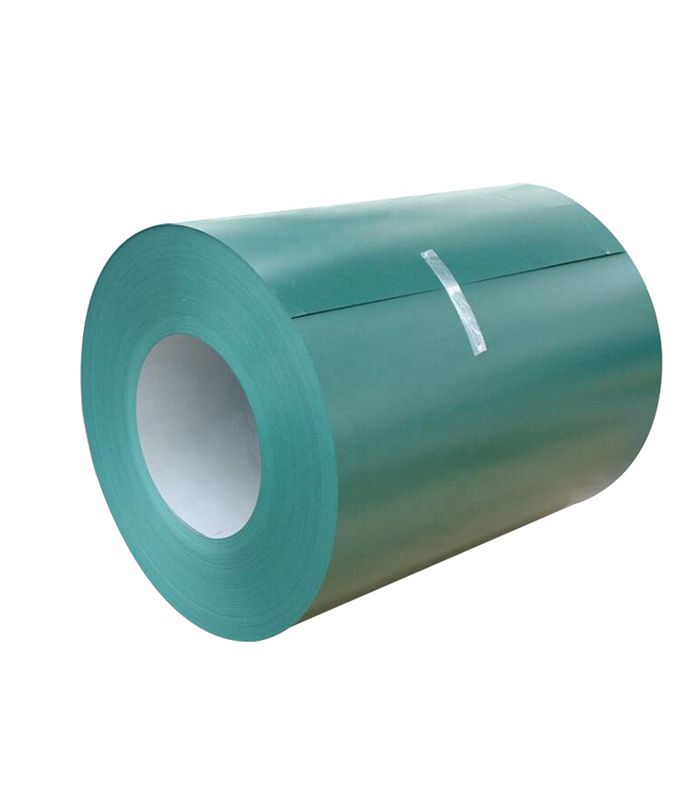

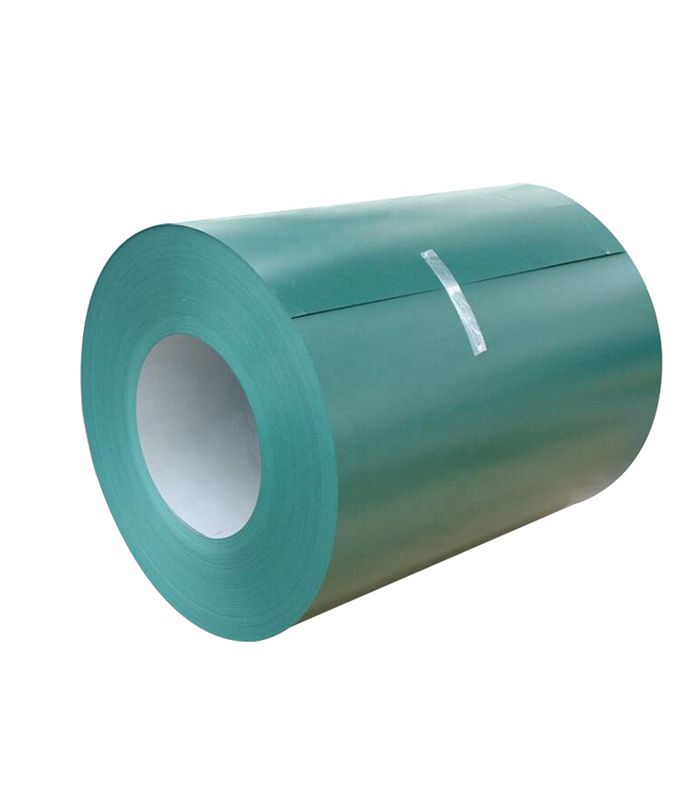

Color-coated steel coils find widespread applications in various industries due to their unique advantages over ordinary steel coils. Some of the industries that commonly use color-coated steel coils include:

1. Construction Industry:

Color-coated steel coils are extensively used in the construction industry for roofing, wall cladding, and architectural applications. They offer a wide range of colors and finishes, allowing architects and designers to create visually appealing and modern structures. Additionally, their corrosion resistance and durability make them suitable for long-lasting and low-maintenance building exteriors.

2. Automotive Industry:

In the automotive sector, color-coated steel coils are used for manufacturing automotive panels, body parts, and trim components. Their enhanced aesthetics and resistance to corrosion make them ideal for producing attractive and long-lasting vehicle exteriors.

3. Appliance Manufacturing:

Color-coated steel coils are used in the production of household appliances, such as refrigerators, washing machines, ovens, and air conditioners. The ability to customize colors and the excellent surface finish provide a sleek and premium appearance to these appliances.

4. Furniture Industry:

Color-coated steel coils are utilized in the furniture industry to manufacture metal furniture pieces like cabinets, shelves, and storage units. The coatings not only offer protection against wear but also add decorative value to the furniture designs.

5. Electronics and Electrical Industry:

In the electronics and electrical industry, color-coated steel coils are used to manufacture enclosures, housings, and cabinets for various electronic devices. The coatings provide protection against environmental factors, contributing to the longevity and reliability of electronic equipment.

Advantages of Color-Coated Steel Coils Compared to Ordinary Steel Coils:

1. Aesthetics: Color-coated steel coils offer a wide range of color options, enabling manufacturers to create visually appealing and attractive products. This is particularly advantageous in industries where aesthetics and design play a crucial role.

2. Corrosion Resistance: The protective coatings on color coated steel coils provide excellent corrosion resistance compared to ordinary steel coils. This feature is particularly valuable in industries that require products to withstand outdoor environments or high humidity conditions.

3. Durability and Longevity: Color-coated steel coils are more durable and have an extended lifespan due to the added protection provided by the coatings. This makes them suitable for long-term applications, reducing maintenance and replacement costs.

4. Cost-Effectiveness: While color-coated steel coils may have a higher upfront cost due to the coating process, they save money in the long run by eliminating the need for additional painting or finishing processes. This enhances production efficiency and reduces overall manufacturing costs.

5. Versatility: Color-coated steel coils are versatile and can be easily shaped, cut, and formed into various product designs. Their flexibility makes them suitable for a wide range of applications across different industries.

6. Environmental Benefits: Some color-coated steel coils use eco-friendly coatings, making them more sustainable and contributing to environmentally conscious manufacturing practices.

In conclusion, color-coated steel coils are widely used in industries such as construction, automotive, appliance manufacturing, furniture, electronics, and electrical due to their aesthetic appeal, corrosion resistance, durability, and cost-effectiveness. They offer distinct advantages over ordinary steel coils, making them a preferred choice for applications that require both functionality and visual appeal. The ability to customize colors and finishes further enhances their usability in various industries, making them a versatile material for many different product applications.

Comments

All Comments ( 0 )