Choosing the right machine vise for your needs requires careful consideration of several factors. Here are some key points to consider:

Vise Type: There are different types of machine vises available, such as drill press vises, milling machine vises, and bench vises. Identify the specific type of vise that suits your intended application and the type of machine you will be using.

Size and Capacity: Consider the size and capacity of the vise. This includes the jaw width, jaw opening, and maximum clamping capacity. Ensure that the vise can accommodate the size and weight of the workpieces you will be working with.

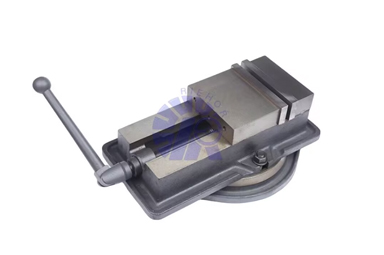

Precision Machine Vise

Jaw Configuration: Evaluate the jaw configuration options available with the vise. The jaws can have different designs, such as flat, V-shaped, or serrated, depending on the nature of the workpieces and the required grip. Consider the specific requirements of your applications and select the appropriate jaw configuration.

Material and Construction: Look for a vise made from high-quality materials that offer durability and stability. Common materials for vises include cast iron, steel, and aluminum. Consider the construction quality, rigidity, and overall strength of the vise to ensure it can withstand the forces exerted during machining operations.

Clamping Mechanism: Assess the clamping mechanism of the vise. The vise may feature a screw-type, hydraulic, or pneumatic clamping mechanism. Consider the level of precision and force required for your work and select a vise with a clamping mechanism suitable for your needs.

Flexibility and Adjustability: Determine if the vise offers flexibility and adjustability to accommodate various workpiece sizes and shapes. Look for features such as movable jaws, adjustable angles, and swiveling capabilities to enhance versatility and ease of use.

Mounting Options: Consider the mounting options available for the vise. Ensure that the vise is compatible with your machine's mounting system, whether it's a bolt-on, clamp-on, or custom mounting arrangement.

Brand Reputation and Reviews: Research reputable vise manufacturers and read customer reviews to gain insights into the quality, performance, and reliability of different vise models. Consider the reputation of the brand and the availability of customer support and warranty services.

It's recommended to consult with industry professionals or machine tool experts who can provide guidance and recommendations based on your specific machining requirements and the type of machine you are using.

Comments

All Comments ( 0 )